Shiliuyun-Xinjiang Daily (Reporter Parizat Abdu) news: In the breeding farm of Modern Animal Husbandry (Changji) Co., Ltd., a unique blend of innovation and tradition is at play. Here, milking machines operate like a "merry-go-rounds", calves are pampered in their own standalone "apartments," and the cows indulge in a luxurious experience with tailor-made high-nutrition "buffets" and soothing massages using cow brushes. This fusion of technology and care exemplifies the cutting-edge approach to dairy farming in the region.

On the morning of July 16, 2024, as the first light of dawn broke through the gentle haze, the livestock farm of Modern Animal Husbandry (Changji) Co., Ltd. in Ashili Kazak Township, Changji City, Changji Hui Autonomous Prefecture, northwest China’s Xinjiang Uygur Autonomous Region, came to life. The dairy cows, adorned in their classic black and white “coats,” commenced their daily routine. They gracefully filed into a rotary milking machine, following a well-trodden path that guides them to their designated places. Skilled workers swiftly perform the pre-milking rituals of cleaning and disinfection, then precisely attach the milking cups. With these meticulous preparations complete, the automated milking process begins.

Photo shows a rotary milking machine automatically milks lactating cows at the livestock farm of Modern Animal Husbandry (Changji) Co., Ltd. in Changji Modern Animal Husbandry Industrial Park, located in Ashili Kazak Township, Changji City, Changji Hui Autonomous Prefecture, northwest China’s Xinjiang Uygur Autonomous Region. (Photo provided by Modern Animal Husbandry (Changji) Co., Ltd.)

Zhang Kai, general manager of Modern Animal Husbandry (Changji) Co., Ltd., shared with the reporter, "This is a heavy-duty rotary milking machine capable of milking 80 cows simultaneously."

"Compared to manual milking or traditional milking equipment, this system is time-saving and labor-efficient, able to complete the milking of 550 cows per hour, nearly doubling the efficiency. Most importantly, the milking equipment simulates the most primitive suckling state of calves, ensuring a gentle milking process where cows can lactate comfortably. Above the milking machine, fans are installed to activate a cooling mode when the temperature in the milking hall exceeds the standard. The freshly squeezed milk does not come into contact with the outside environment but is channeled through a condensation pipeline into the storage room." As Zhang introduced the heavy-duty rotary milking machine, his face was filled with excitement and pride.

"Consequently, they produce more high-quality milk," Zhang said. "Currently, the company has over 3,500 dairy cows in stock, including more than 1,900 lactating cows, producing over 70 tons of fresh milk daily."

Photo shows a feeder feeds calves at the livestock farm of Modern Animal Husbandry (Changji) Co., Ltd. in Changji Modern Animal Husbandry Industrial Park, located in Ashili Kazak Township, Changji City, Changji Hui Autonomous Prefecture, northwest China’s Xinjiang Uygur Autonomous Region. (Photo by Hu Yaning)

After birth, the calves are moved into specially designed calf islands, where they are housed individually and fed by dedicated staff. This isolated rearing method allows for constant monitoring of the calves' health, reducing the risk of cross-infection and lowering the incidence of diseases such as diarrhea and pneumonia.

Moreover, on the day of birth, each calf is fitted with a unique electronic ear tag. The tag bears a number, serving as an identifier, which facilitates the caregivers to monitor the calves' dietary ratios, health and vaccination status, and future milk production around the clock. Additionally, the information from the ear tags is automatically uploaded to a database. This database contains electronic records for each cow, making all relevant information easily accessible and transparent.

Photo shows a calf with electronic ear tags on both ears at the livestock farm of Modern Animal Husbandry (Changji) Co., Ltd. in Changji Modern Animal Husbandry Industrial Park, located in Ashili Kazak Township, Changji City, Changji Hui Autonomous Prefecture, northwest China’s Xinjiang Uygur Autonomous Region. (Photo by Hu Yaning)

After enjoying the privilege of individual housing for over two months and passing all physical tests, the calves will be moved to smart cow sheds to start communal living.

According to Zhang, rice husk 'soft beds,' cow brushes, and intelligent temperature-controlled shower systems are all standard equipment in the cow sheds. In addition, the sheds are equipped with negative pressure fans, automatic feed trucks, and automatic manure cleaners, among other modern devices. These devices are all fitted with intelligent control sensors that can collect operational data around the clock, monitor the temperature, humidity, and ammonia concentration in the cow sheds. If any indicators are abnormal, staff can control the operation parameters of fans, water curtains, sprays, lighting, and other equipment through a mobile app, making the cows' “living” more comfortable.

Behind the comfortable life of dairy cows is the support of the deep integration of big data, the Internet of Things, and artificial intelligence technologies.

The Ashili Kazak Township, where the Changji Modern Animal Husbandry Industrial Park is located, lies within the internationally recognized golden milk source belt. "Currently, the industrial park has 48 large-scale breeding farms, including Modern Animal Husbandry (Changji) Co., Ltd., nine mechanized milking halls, with a mechanization rate in dairy cow breeding exceeding 70 percent, and it produces 250 tons of high-quality fresh milk daily," said Wang Chunguo, general manager of Changji Agricultural Investment Development and Operation Co., Ltd.

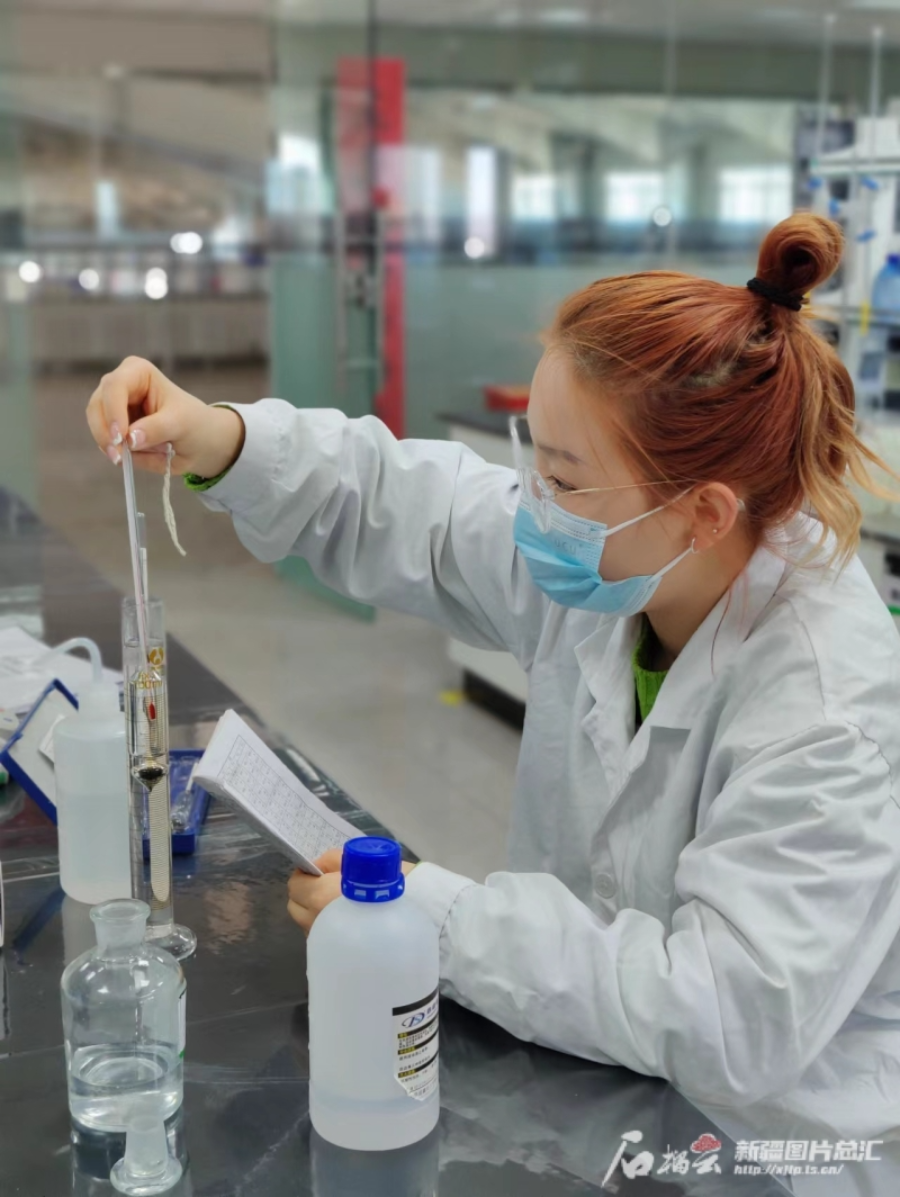

Photo shows a worker tests fresh milk in the testing workshop of Modern Animal Husbandry (Changji) Co., Ltd. in Changji Modern Animal Husbandry Industrial Park, located in Ashili Kazak Township, Changji City, Changji Hui Autonomous Prefecture, northwest China’s Xinjiang Uygur Autonomous Region. (Photo by Hu Yaning)

Zhang introduced the company's future plans, indicating that they would further renovate the cow sheds and milking halls, as well as facilities such as intelligent fans and smart sprinklers. He mentioned that the company will introduce feed-pushing robots to achieve a more economical and efficient mode of production. Furthermore, the company aims to complete the first phase of their full-load breeding target of 5,000 cows, with a daily production of fresh milk exceeding 100 tons, and is committed to setting a benchmark for smart dairy farming in Xinjiang.

(A written permission shall be obtained for reprinting, excerpting, copying and mirroring of the contents published on this website. Unauthorized aforementioned act shall be deemed an infringement, of which the actor shall be held accountable under the law.)